When we pick out an outfit for the day, most of us don’t think twice about what it’s made from — or where it came from. But behind every piece of clothing lies a story, and for much of the fashion industry, that story is damaging. With the textile and apparel sector contributing nearly 6% to 8% of global carbon emissions, the environmental impact of our clothing choices is bigger than we often realize. It’s clear that something needs to change — and surprisingly, that change might start with something as ordinary as a banana plant.

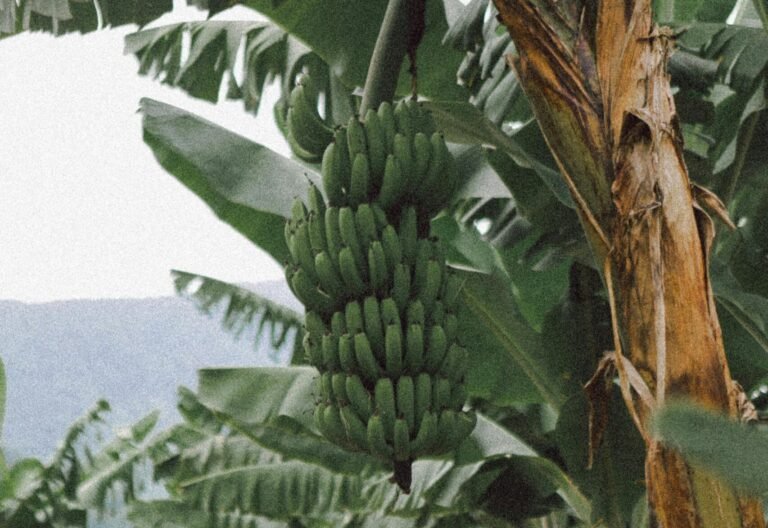

After producing fruit just once, banana plants are usually chopped down and discarded. But what’s left behind — the thick pseudostem, leafy stalks, and peels — is far from useless. In fact, more than half the plant’s mass becomes biomass waste, adding up to over 550 million tons globally each year. If left to decompose, this waste releases harmful gases like methane and nitrous oxide into the atmosphere. However, hidden within this discarded material is a fiber that’s rapidly gaining attention for all the right reasons: Banana Fiber.

What makes this fiber truly special is that it’s derived from agricultural waste — meaning no new land, no extra water, and no chemical inputs are needed for its production. In a world increasingly concerned with sustainability, that’s a big deal. Compared to cotton, which demands vast amounts of water and pesticides, Banana Fiber is incredibly low-impact. Its carbon footprint stands at just 0.48 kg of CO₂ per ton — over 94% lower than that of cotton — and its water usage is dramatically less.

But this isn’t just about being eco-friendly. The technical qualities of Banana Fiber are just as impressive. It’s up to ten times stronger than jute or coconut fibers, naturally biodegradable, and resistant to water, fire, tension, and grease. It’s also odorless, durable under high temperatures, and chemically inert, making it an attractive alternative not only for fashion but also for industrial use, packaging, insulation, and even construction. And yet, despite all these strengths, Banana Fiber remains largely underused in the mainstream fashion world.

One of the main reasons for this is that turning coarse banana stem into soft, wearable fabric requires a refining step called degumming — a process that’s still evolving. But innovation is accelerating, and more designers and fabric developers are now experimenting with this promising material. In the meantime, most of the global attention around Banana Fiber has gone toward industrial and composite applications, leaving its potential in everyday clothing largely untapped.

That’s where brands like Evara step in. As one of the few labels pioneering its use in fashion, Evara is redefining what it means to dress consciously. By sourcing discarded banana stems and turning them into wearable textiles, they transform agricultural waste into beautiful, breathable garments. Their process focuses on minimal water use, ethical sourcing, and thoughtful design — proving that sustainable clothing can still be elegant and modern. Through Banana Fiber, Evara offers consumers a way to support circular fashion while wearing something unique and planet-friendly.

In a time when climate headlines dominate the news and eco-anxiety is rising, fashion can feel like a difficult space to navigate. But materials like Banana Fiber show us that alternatives do exist — ones that are rooted in nature, rich in potential, and kinder to the earth. This isn’t just a trend; it’s a rethinking of what fashion can be. It’s about turning overlooked waste into everyday wear. Choosing materials that give back instead of taking away.

So the next time you shop, pause and ask — what is this made from? Where did it come from? And could something like Banana Fiber be part of your wardrobe? The future of fashion doesn’t have to be synthetic. It can be circular, conscious, and surprisingly close to home.

Turn waste into wardrobe. Choose better. Shop eco-conscious fashion made from Banana Fiber at shopevara.in today.

Closing the cycle: Circular economy strategies for the textile industry using banana farming waste